Straen Energy

Straen Energy AS was established in November 2017, based on an idea matured since 2007 “How to combine the complex and costly gas system during production of oil and gas into a compact unit”.

During 2013 -2017 further work was performed to develop and optimize the concept.

The concept is based on compressing separated gas from the well stream by use of a motive fluid (water or glycols). The operational sequencies are described in CSU Development. The main difference from a traditional separation system is the substitution of conventional centrifugal compressors by pumps, using fluid as a motive compression medium.

During 2018 a K-Spice Dynamic simulation model was built in order to verify functionality and design. This dynamic model makes it possible to prove the concept and build a base case with fluid characteristics, sizes, control philosophy and energy budget.

An updated patent was filed in 2018, ref. P28738NO00.

The company was certified according to ISO 9001:2015 in March 2019.

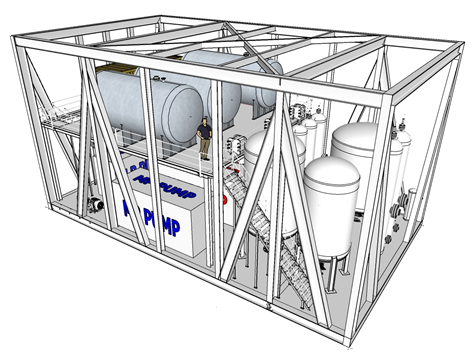

CSU – Compact Gas Compression and Separation Unit

Benefits

Benefits

- Exclusion of compressors – Compression with improved efficiency and flexibility regarding pressure differential and flow rate

- Lower maintenance costs by

-

- Less equipment

-

- Simplified sealing solutions

- Compact design, smaller foot print

- Less weight

- Increased Process safety

-

- Fewer potential gas leakage points

- Pressure stage independent

-

- Compared to a factor of 3 – 5 between individual stages for a centrifugal compressor

- No lower limit for gas compression quantities

-

- Compared to centrifugal compressors, which need recirculation of gas by lower gas quantities

- Exclusion of coolers and scrubbers at the individual compressor stages

- Lower CAPEX i.e. cost savings in the order of 50 %; when comparing the CSU to the alternative use of a compact conventional centrifugal compressor unit

- Lower OPEX by isothermal compression and lower maintenance cost